Point Of Use(POU) Abatement

Semiconductor manufacturing process uses a wide variety of highly toxic, pyrophoric, hazardous or corrosive process gases. Abatement equipment installed in the Sub Fab must meet NEA and FSSD requirements.

Flammable Waste Gases from Semiconductor manufacturing Tools such as Hydrogen is required to be treated or dilated below 50% flammable limit before discharge into Facility Exhaust.

Toxic and Corrosive Waste Gases from manufacturing Tools such as HCl,NF3 is required to be treated below TLV level of the Gases before discharge into Facility ACID Exhaust.

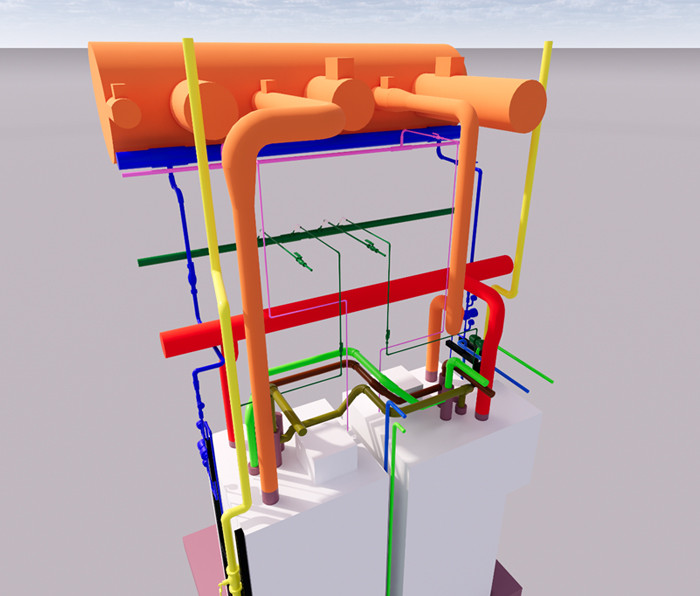

Typical Semiconductor facility will have the following Exhaust Systems: Flammable Gas Room Exhaust, ACID Exhaust, Caustic Exhaust and General Exhaust.

Our Solution

Provide Engineering solutions that will meet code compliance, 365 days operation , Energy Efficiency and continuous monitoring at Facility SCADA.

Design review with End user at 30%,60% and 90%.

Provide Design Solutions based on best available POU Abatement in the market and available utilities in facility.

Market Sourcing , Tender Review and Appoint Supplier.

Conduct HAZOP study with Customer and Abatement Manufacturer.

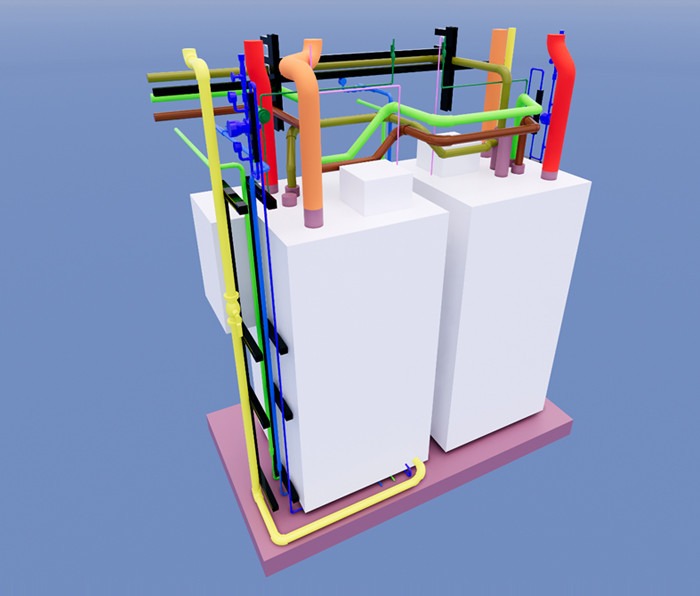

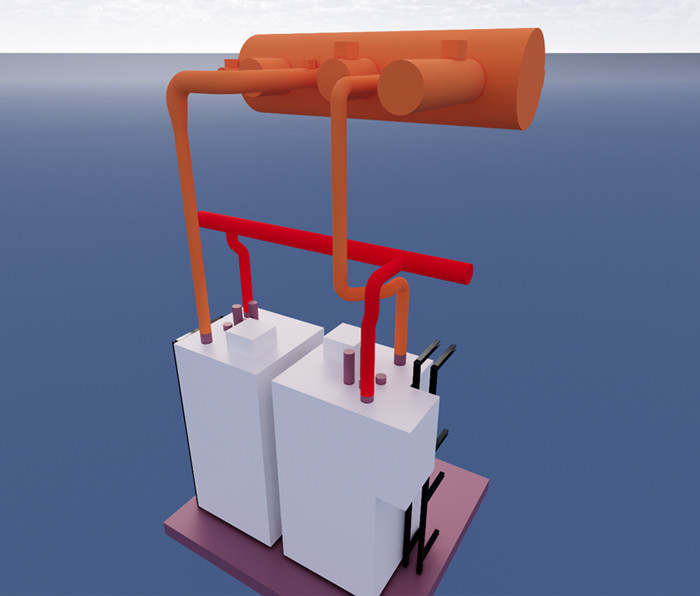

In corporate Abatement in the Sub Fab Tool design and design the Utilities requirements.